Why asset integrity management is crucial for hydrocarbon facilities new and old

Blogs - Aug 19 2021

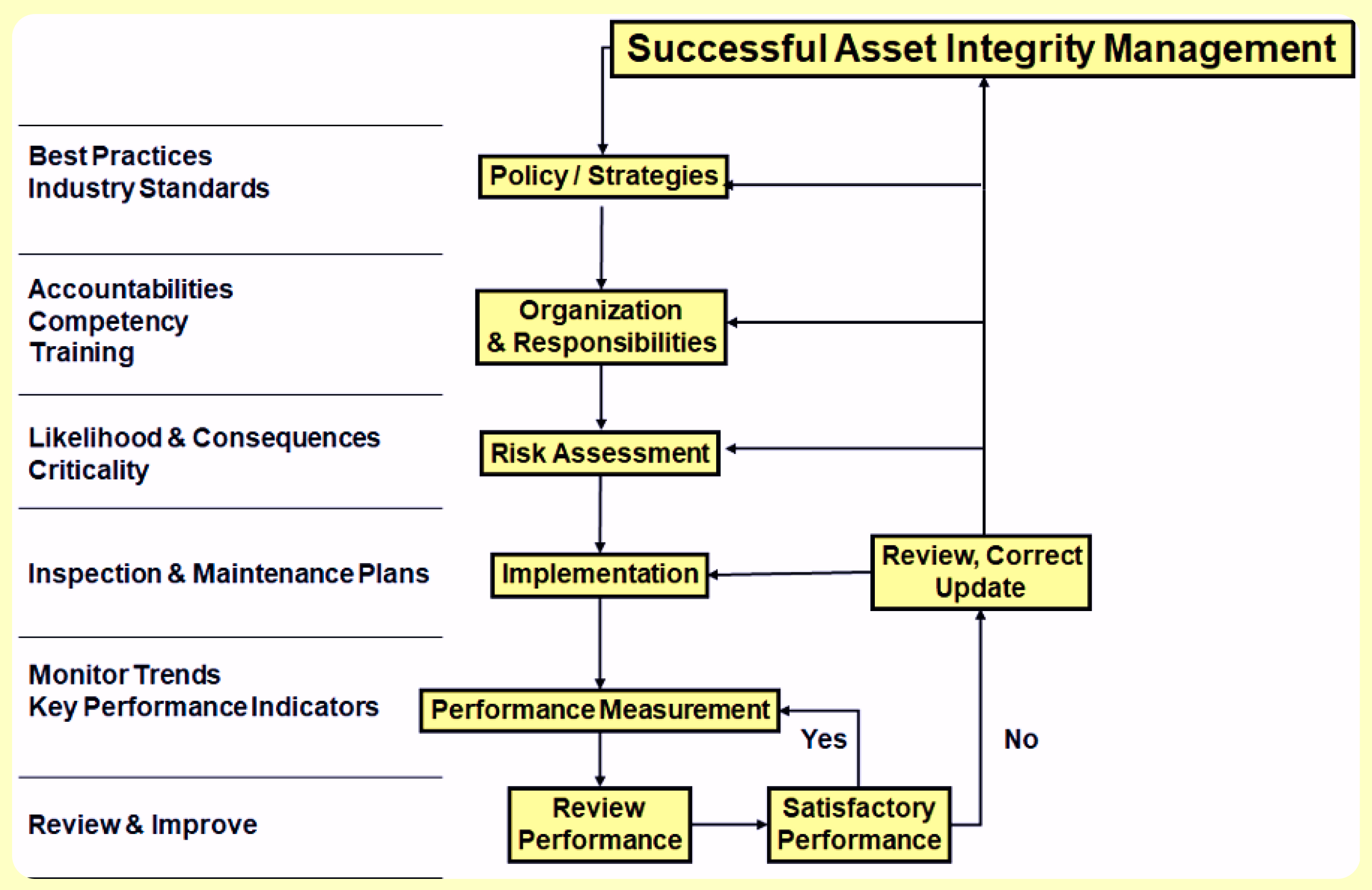

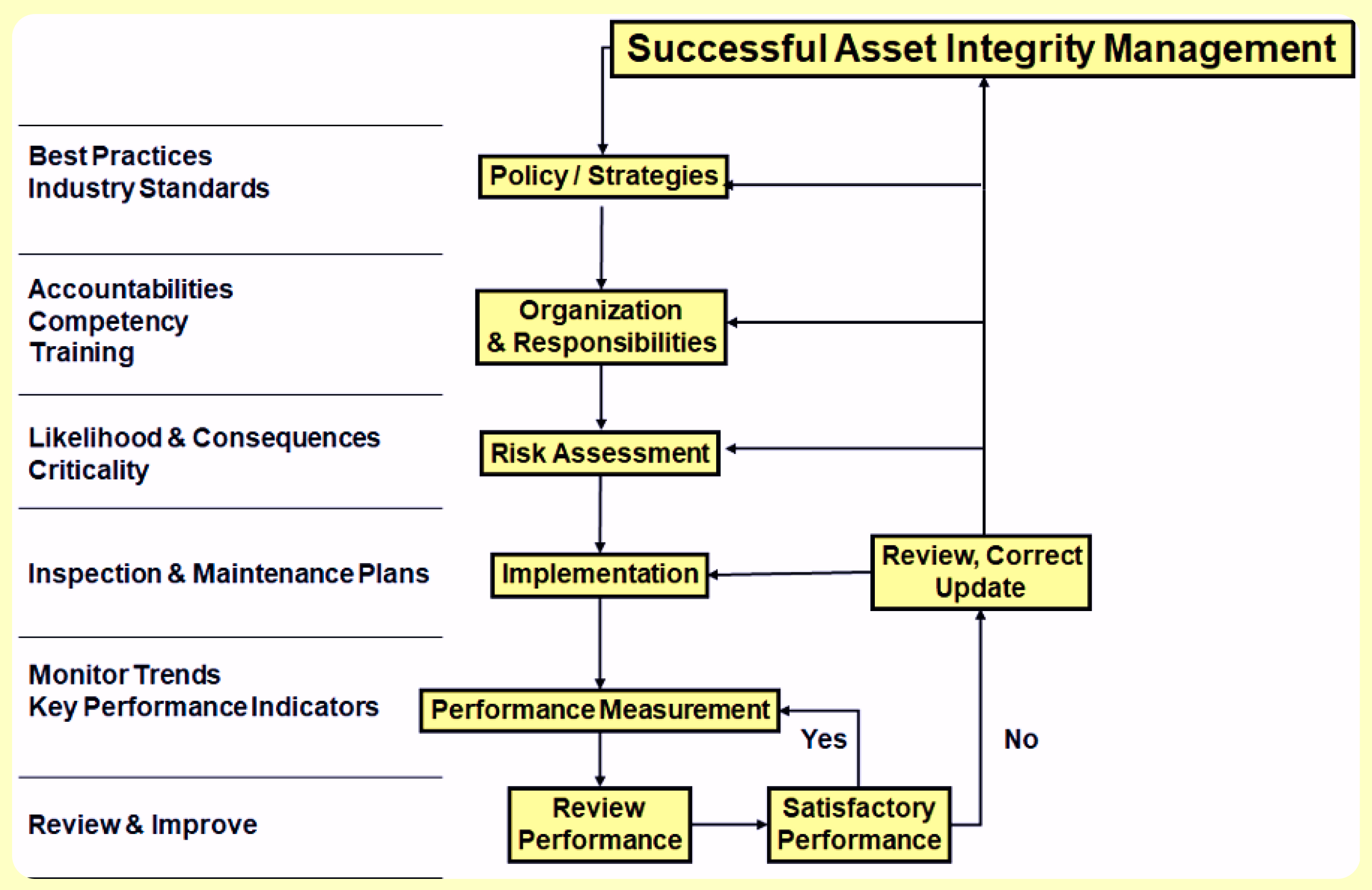

What is the problem? Operating a hydrocarbon facility is a complex and challenging business. Assets in refineries, gas plants and petrochemical plants are subjected to varying temperatures and pressures, corrosive, volatile and toxic substances. Although the threats affecting the mechanical integrity of assets are identified and dealt with at an early stage in the design life, these nevertheless do manifest themselves because of either inadequate procurement and construction, inadequate quality assurance/quality control, process changes or aging during the lifecycle of the plant. How do we fix it? The first step to fixing a problem is to acknowledge the problem and develop a framework with policies and strategies to counter the threats affecting asset integrity and safety thus ensuring the sustainability of the business. An example of such a framework is shown below. In addition to policies and strategies, work processes for engineers and managers are also required to assign responsibilities and reporting mechanisms. Implementation of safeguards and monitoring using state-of-the-art technologies constitute the “doing” part of the framework. Operational data is then collected, analysed, and trended to identify early signs of incipient failures for immediate resolution. The framework will be incomplete without regular reviews and audits to close any gaps that may exist and drive continuous improvement. Why is all this needed? A successful asset integrity management yields (i) improved plant integrity and safety, (ii) reduced failures, (iii) maximum plant availability, (iv) optimized monitoring and maintenance expenditure and (v) reduced lost profit opportunity. All these benefits contribute to the long-term sustainability and growth of the business without compromise to health, safety, and the environment.

-

OLAX makes progress on major milestones for B...

Sep 21 2021 News

-

Why asset integrity management is crucial for...

Aug 19 2021 Blogs

-

OLAX Engineering Summer Interns Q/A

Aug 19 2021 Blogs

-

Project progress review in Reading by Kabiru...

Jun 11 2021 News

-

OLAX wins major PMC contract with BUA Group

Mar 06 2021 News

-

OLAX sees continued expansion in UK and Niger...

Dec 12 2020 News